AAA is a leading CNC pipe cutting machine supplier in China. We would like to share professional knowledge and maintenance of CNC pipe cutting machines with the users. Today, we are going to teach you how to maintain the saw of the CNC pipe cutting machine.

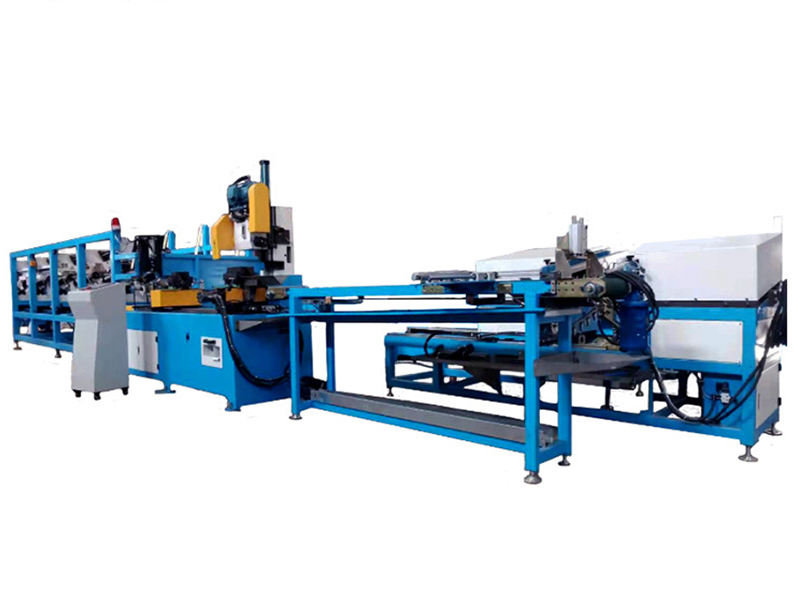

AAA-Q315YFA | Automatic aluminum tube cutting machine for sale in China

Features of pipe cutting machines:

The 90° fully automatic pipe cutting machine with oil pressure as the power is suitable for pipe cutting of different shapes, the performance is stable and the operation is simple and fast.Parameter of pipe cutting machine

| Model | AAA-Q315YFA |

| Power | Three-phase,380V,50HZ |

| Blade speed(RPM) | 44/88 |

| Blade Size (mm) | 250-350 |

| Cooling mode | coolant liquid |

| Clamping mode | jaw vice (single side) |

| Feeding length(mm) | 30-1000mm |

| Oil pressure | 10-30 |

| Weight (Kg) | 600 |

| Machine size LxWxH(mm) | 2000x800x1600 |

1. In order to ensure the safe use of the automatic pipe cutting machine, we should carefully check whether the various parts of the machine are in the normal working range before starting up, and check whether there are any loose screws or air pipe leakage. The automatic pipe cutting machine ensures that the start-up operation is carried out under the correct conditions.

2. The automatic pipe cutting machine must cut off all power supplies during maintenance and repair work and is equipped with an obvious warning sign to ensure safety.

3. During the use of the pipe cutting machine, the lubrication system should be checked regularly, and lubricating oil should be added regularly, so as to ensure the lubricity of each part, and give full play to the performance of each part to extend the service life.

4.The best way to maintain the automatic pipe cutting machine is to operate the pipe cutting machine normally, check the operating conditions at any time during operation, pay attention to details, and find and solve problems in time.

Conclusion

Maintenance is the key point to keep a machine running well. If you want more further information, please contact us today! More information about our CNC pipe cutting machine, please visit https://www.aaa-machine.com/.