In the modern industrial era, the automatic chamfering machine has become an indispensable machine in many industries, because it can modify the products. So, do you how the automatic chamfering machine actually benefits the business? In this post, the author will give a further introduction to automatic chamfering machines.

An automatic chamfering machine is used for easing or smoothing the edges of tables, and corners of counter tables. The automatic chamfering machine serves various purposes across different industries due to its ability to perform precise cuts or grinds on the edges of workpieces. The automatic chamfering machine is widely seen in furniture, public projects, the mechanical industry, glass manufacturing or cutting industry, etc. The author has given a full introduction to the applications of the chamfering machine: Complete Introduction to Chamfering Machines

Most people may wonder why the chamfering machine is so popular in such a wide range of industries. In this section, the author will present the advantages of chamfering machines.

One of the primary advantages of chamfering machines is their ability to reduce labor costs significantly. These machines automate the chamfering process, minimizing the need for manual intervention, thereby optimizing labor resources and cutting down on associated costs. Also, it can shorten the training cycle, so it improves the speed and flexibility of the enterprise.

The chamfering machine is designed to automatically change tools according to the requirements of the workpiece. The precision and controlled operation of this machine reduces wear and tear on tools, ensuring their longevity and minimizing the frequency of replacements.

The precision offered by chamfering machines, especially the cnc chamfering machine, is unparalleled. These machines are engineered to execute chamfering with utmost accuracy, resulting in consistently high-quality outputs that meet stringent industry standards.

Compared with manual operation, the chamfering machine produces less noise and dust during the working process. Thus, the introduction of chamfering machines positively impacts the working environment. With reduced noise levels and a more organized workflow, these machines contribute to a safer and more pleasant workplace for employees.

An automatic chamfering machine is a specialized machine, so various models have been developed such as a chamfering machine for round bars and a pipe chamfering machine. Thus, due to its specialized design, the precision and consistency of the chamfering process result in smooth, uniform edges that enhance the overall quality and aesthetics of the finished products.

The automatic chamfering machine offers remarkable customizability, allowing industries to tailor chamfering processes according to specific requirements. From angle adjustments to material-specific settings, the flexibility of chamfering machines accommodates diverse production needs.

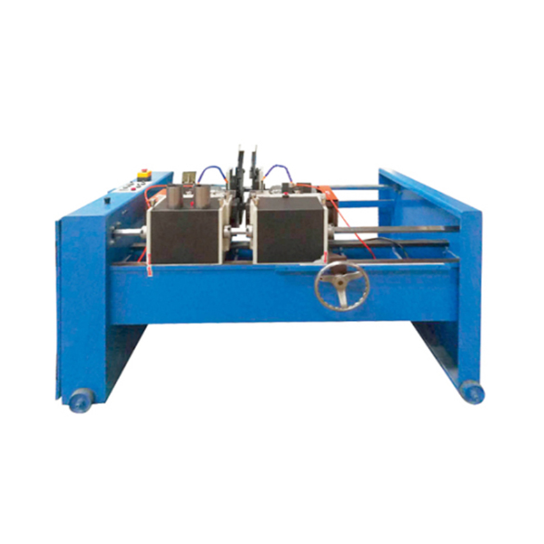

An automatic chamfering machine is designed with a compact structure without compromising on functionality. Its compact design not only saves valuable space on the production floor but also ensures ease of integration into existing manufacturing setups.

Although the automatic chamfering machine has a complex physical structure, it has a user-friendly operation system. Just a simple press or touch, you can easily achieve the operation.

The automatic chamfering machine also focuses on the safety features. Safety mechanisms and protocols integrated into these machines ensure a secure working environment for operators. And, the automatic chamfering machine also reduces the dependence on personnel skills, as a result reducing the operational risks.

Finally, the automatic chamfering machine has a complex mechanism system and user-friendly operation system meanwhile it provides precise and consistent edge finishing. Thus, it makes a contribution to improved product quality, safety, and functionality across a wide range of applications.

AAA is a chamfering machine manufacturer, selling efficient and accurate automatic chamfering machines to various industries.

Our main products include pipe cutting machine, aluminum cutting machine, tube bender, machining center and pipe forming machine. We also customize machine or production line for customers.