In today's fast-paced production world, efficiency is key. Textile and automotive industries rely largely on precision cutting operations to assure product quality and accuracy. Traditional manual cutting methods, while effective to some extent, often fall short in terms of speed, accuracy, and consistency. This is where automatic cutting machines step in, revolutionizing production processes and offering a myriad of benefits that propel businesses forward.

Automatic cutting machines leverage advanced technologies such as laser or waterjet cutting systems to ensure unparalleled precision and accuracy in every cut. These machines work with micrometer-level accuracy, ensuring consistent results even with intricate shapes and changing thicknesses. Whether it's intricate patterns in textiles or precise cuts in metals, automatic cutting machines excel in delivering high-quality outcomes, minimizing material waste and rework.

One of the most significant advantages of automatic cutting machines is their ability to significantly boost productivity. Unlike manual cutting methods, which rely on human operators and are subject to fatigue and human error, automatic cutting machines operate continuously without breaks. This continuous operation leads to increased throughput and quicker production cycles. Businesses that streamline the cutting process may easily meet tight deadlines and handle enormous volumes of work, increasing overall efficiency and competitiveness.

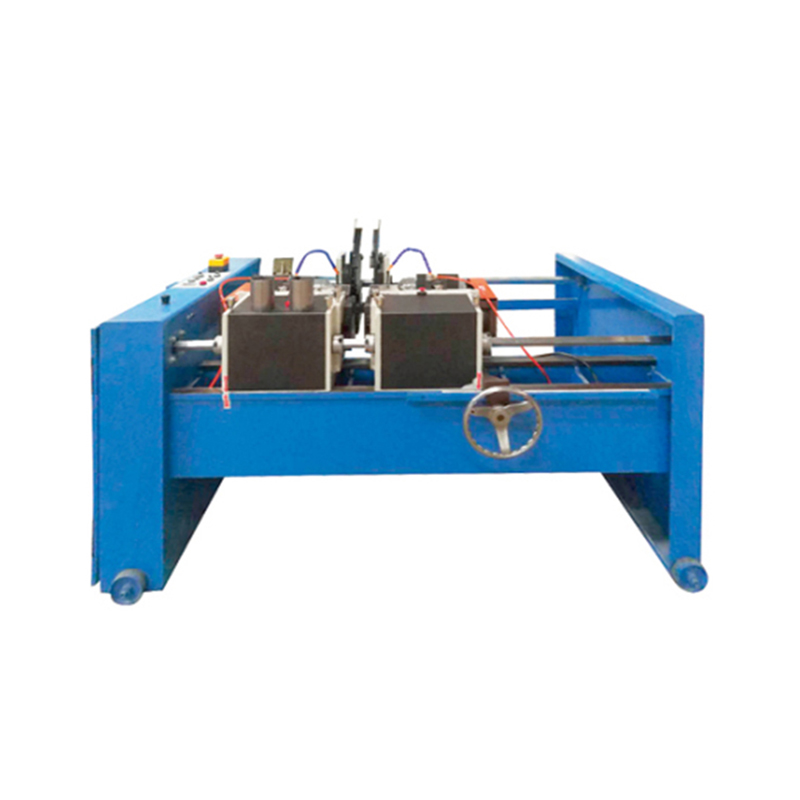

Fully Automatic Cutting Machine

While the initial investment in an automatic cutting machine may seem substantial, the long-term cost savings are undeniable. Businesses that automate the cutting process can decrease labor costs associated with manual cutting, eliminate material waste through optimum cutting patterns, and reduce the possibility of mistakes that could result in costly rework or scrap. Additionally, the increased productivity and efficiency offered by automatic cutting machines lead to a quicker return on investment, making them a cost-effective solution in the long run.

Automatic cutting machines are highly versatile and adaptable to various materials and applications. These machines can easily handle a variety of materials, including fabric, leather, metal, foam, and composites. Furthermore, they can accommodate different shapes, sizes, and thicknesses, offering unmatched flexibility to meet diverse manufacturing needs. This adaptability allows organizations to optimize their operations by unifying cutting processes, eliminating the need for many specialized equipment, and optimizing floor space.

Manual cutting processes often pose safety risks to workers, especially when dealing with sharp tools or heavy machinery. Automatic cutting machines eliminate many of these hazards by minimizing direct human involvement in the cutting process. Operators may manage the equipment from a safe distance, which reduces the risk of workplace mishaps and injuries. Furthermore, automated cutting machines have safety features like sensors and emergency stop mechanisms to improve worker safety.

Consistency is key to maintaining high-quality standards in manufacturing. Automatic cutting machines ensure uniformity in every cut, eliminating variations that may arise from human error or fatigue. Businesses with precise control over cutting settings may adhere to strict quality control methods and provide goods that meet or surpass consumer expectations. This consistency not only enhances product quality but also reduces the need for quality inspections and rework, leading to improved overall efficiency and customer satisfaction.

Modern automatic cutting machines are often equipped with software interfaces that integrate seamlessly with digital design and production systems. This connectivity enables smooth data transmission, allowing organizations to automate operations, maximize material consumption, and respond quickly to design modifications or customized requests. By leveraging digital technologies, businesses can achieve greater efficiency, agility, and responsiveness in their cutting processes, staying ahead of the curve in today's rapidly evolving market.

By optimizing material usage and minimizing wastage, automatic cutting machines contribute to environmental sustainability. Reduced waste and energy usage compared to manual cutting processes result in a lower carbon footprint for enterprises, which aligns with worldwide initiatives to promote eco-friendly production practices. Embracing automated cutting solutions not only drives operational efficiency but also supports a greener, more sustainable future for the manufacturing industry.

These machines provide a competitive advantage in today's changing industrial scene by combining accuracy, productivity, cost savings, and environmental sustainability. If you are looking for top-quality automatic cutting machines, look no further than AAA machine. We are a leading cutting machine supplier, offering various cutting machines. Visit our site for more product details today!

Our main products include pipe cutting machine, aluminum cutting machine, tube bender, machining center and pipe forming machine. We also customize machine or production line for customers.