Do you ever notice that each finished product has a smooth and even surface, but the unfinished products tend to be rough? And, do you know how the products get great change? As a matter of fact, the edge deburring machine makes a contribution to perfecting the products. In this post, the author will guide you to explore the deburring machine.

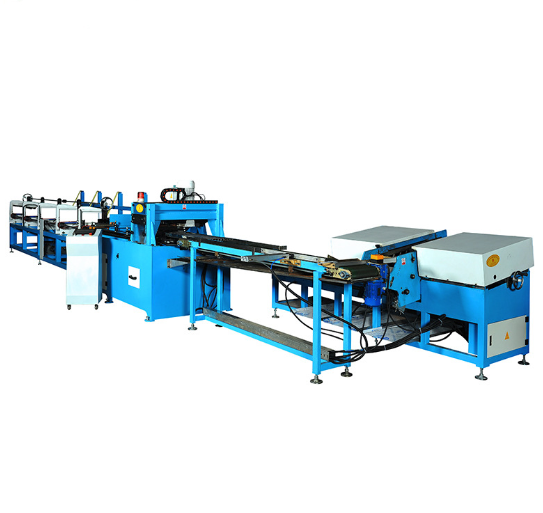

The deburring machine is a specialized machine to remove burrs. The burrs are unwanted rough edges, projections, or small pieces of material that remain attached to a workpiece (e.g. metal, plastic, wood, ceramics, etc.) after cutting machining, or fabrication processes. The deburring machine aims to provide consistent and high-quality products with high efficiency.

The deburring working principle is simple. The deburring machine has one or more tools for smoothing burrs out of the machined metal. And, the exact working method depends on the type of deburring machine being used, each with its specific approach to achieve smooth, burr-free surfaces. In this part, the author will illustrate on how different types of deburring machines work:

These machines use a tumbling or vibrating action in a container or chamber filled with abrasive media, compounds, and workpieces. As the machine vibrates or tumbles, the abrasive media continuously rubs against the workpieces, effectively removing burrs and irregularities. The constant motion and friction between the media and workpieces smooth out edges and surfaces.

They typically feature rotating brushes, abrasive discs, or tools that move against the workpiece's edges, holes, or internal surfaces. The rotating action of the tools allows them to target specific areas where burrs need to be removed. These machines often provide precision deburring in localized spots.

Utilizing abrasive belts or wheels, these machines grind, sand, or polish the edges and surfaces of workpieces. The workpiece is brought into contact with the abrasive belt or wheel, and the rotational motion of the belt or wheel removes burrs and imperfections, creating smoother surfaces.

They use rotating brushes with abrasive bristles that come into contact with the workpiece's edges and surfaces. The abrasive action of the brushes effectively removes burrs and irregularities without damaging the material. These machines are suitable for applications where a softer touch is needed.

Most people may underestimate the importance of deburring. As a matter of fact, the deburring can benefit workers, operators, and customers. In this section, the author will tell you why the deburring is necessary.

Burrs and sharp edges, especially the burrs and sharp edges in metal, left on workpieces can pose safety hazards to workers handling these components. Removing these burrs prevents injuries during assembly, handling, or general use.

Burr-free edges contribute to the overall quality of the product. Tiny burrs can affect the functionality of parts, interfere with proper assembly, or compromise the performance of machinery or equipment. This is because most machines have complex mechanism systems that easily get affected.

In manufacturing, consistency is key. Deburring ensures uniformity in part dimensions and functionality, maintaining precision and meeting quality standards consistently across production batches.

Smooth, clean edges enhance the appearance of finished products. Deburring contributes to a professional finish, especially in industries where aesthetics matter, such as consumer goods or electronics.

Burrs can hinder the functionality of parts, affecting their fit, movement, or interaction with other components. Removing burrs ensures that parts function as intended without interference or obstruction.

Burrs can cause excessive wear on machinery or adjacent parts in contact. By removing these protrusions, the risk of premature wear and damage to components is minimized.

For components that require subsequent processes like welding, coating, or assembly, deburring ensures that these processes can be performed smoothly and effectively.

Deburring machines come with various prices because they are customizable in features and sizes. Therefore, if you want to get a precise price, you need to consult deburring machine suppliers.

At last, the edge deburring machine is a practical tool to improve finished workpieces. Thus, it is a good investment for your business. If you are looking for a reliable edge deburring machine, you can buy machines from AAA. AAA offers an extensive catalog of edge deburring machines. AAA is one of the most professional deburring machine suppliers in China, and is capable of providing the most specialized custom deburring machine.

Our main products include pipe cutting machine, aluminum cutting machine, tube bender, machining center and pipe forming machine. We also customize machine or production line for customers.